PE Jaw Crusher

Description

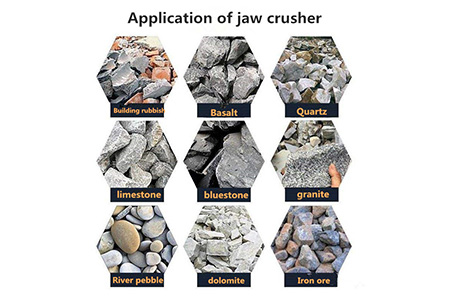

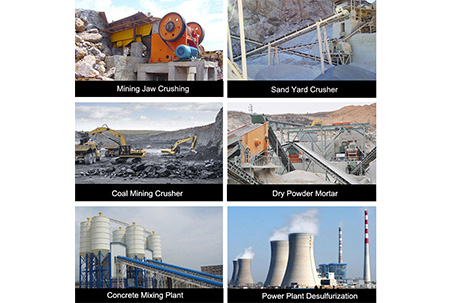

Jaw crusher is mainly used for medium crushing and fine crushing of raw materials. The crushing mode is curved extrusion type. It has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, simple maintenance and economic operation cost. It is widely used in mining, smelting, building materials, highway, water conservancy, chemical industry and many other departments to crush all kinds of materials with compressive strength less than 320 MPa.

Product advantages

Jaw crusher has the following performance characteristics:

1. The crushing ratio of jaw crusher is about 15, and the particle size is uniform;

2. It has a large range of adjustment and reliable operation;

3. The jaw crusher has high production efficiency and low energy consumption. Compared with ordinary fine jawbone, the processing capacity of jaw crusher is increased by 20-35% and the energy consumption is reduced by 15-20%;

4. The crushing chamber of the crusher is deep and there is no dead zone, which improves the feeding capacity and output;

5. Under the same process conditions, the service life of jaw plate can be extended by more than 3-4 times, especially for high abrasive materials;

6. The lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small.

Working Principle

The jaw crusher is mainly composed of pull rod, spring, adjusting pad, adjusting seat, elbow plate, moving jaw, eccentric shaft, fixed wedge of moving jaw, moving jaw, side guard plate, fixed jaw plate, frame and other equipment. The crushing mode of PE Series jaw crusher is curved extrusion type. The belt and pulley are driven by motor, and the moving jaw moves up and down through eccentric shaft, When the moving jaw rises, the angle between the elbow plate and the moving jaw becomes larger, which promotes the moving jaw plate to approach the fixed jaw plate. At the same time, the material is crushed by extrusion, rubbing and grinding;

When the moving jaw goes down, the angle between the elbow plate and the moving jaw becomes smaller, and the moving jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the crushed materials are discharged from the lower opening of the crushing cavity. With the continuous rotation of the motor, the crushing mobile jaw makes periodic crushing and discharging to realize mass production.

South America crushing machinery product supplier Hengtong Machinery Brazil PE Jaw Crusher overseas product service station The reason for becoming a PE Jaw Crusher long-term partner, the core point of which is "word of mouth" - Hengtong Machinery firmly believes that word of mouth is a marketing method, and "wine is not afraid of deep alley" is the reflection of the peak of word of mouth marketing. PE Jaw Crusher The technical content of the product is often the key to crushing ore tailings PE Jaw Crusher customer selection and judgment! In recent years, Hengtong Machinery is injecting new technology into its products and upgrading them. Strength comes from technological innovation, and reputation comes from stable quality! PE Jaw Crusher Only by creating valuable products in the crushing ore tailings industry and winning the reputation of customers can Hengtong Machinery move to the industry stage. Hengtong Machinery principal believes that to make crushing ore tailings industry customers recognize your company, you must first have the PE Jaw Crusher product you can produce. Hengtong Machinery has always believed in the principle of doing things: no matter how many things you have made, Hengtong Machinery flagship products PE Jaw Crusher should always maintain a good standard, so that crushing ore tailings PE Jaw Crusher customers will give back good comments after using them. Then the word of mouth of crushing ore tailings PE Jaw Crusher products will go out.