Granite Crusher

Description

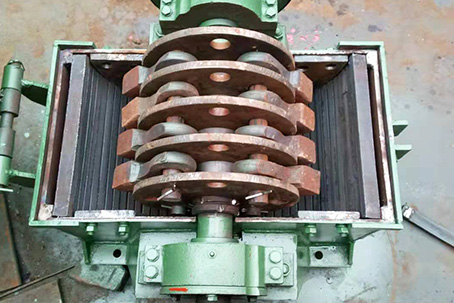

The granite hammer crusher is mainly composed of rotor assembly, muffler, shell, counterattack frame and driving part. The hammer head of the crusher mainly hits the ore in the upper cavity.

The impact of the ore on the counter-attack frame and the collision between the ore cause the ore to be broken. After the raw ore is fed into the feed inlet of the crusher through heavy-duty feeding equipment (such as an adjustable-speed plate feeder), it falls into the crushing cavity between the high-speed rotating rotor driven by a narrow V-belt and the counterattack frame.

The hammer was initially broken. After the initial crushing, the material is further crushed again between the rotor and the counter-attack frame during the downward movement, and then the lower crushing cavity formed by the muzzle and the rotor is crushed until the particle size is smaller than the size of the slit and is discharged from the lower part of the cavity.

Product advantages

1.This product has the characteristics of small size, light weight, simple structure, easy operation and maintenance, uniform product size, and high production capacity.

2.The hammer head and the sieve plate are made of chromium-manganese alloy material, which has stronger impact resistance and wear resistance.

3.Advanced design technology, strong structure, impact resistance.

4.High yield and good grain shape.

Product use

This equipment is widely used in cement plants, large aggregate production line projects, mineral processing equipment, and ceramic raw material crushing.The hammer crusher is suitable for crushing various medium-hard and brittle materials such as limestone, coal gangue, gypsum, shale, steel slag, slag, pebbles, etc., with a compressive strength of less than 180MPa.

The reason why many Granite Crusher customers choose Western Europe Crushing equipment product supplier Hengtong Machinery Spain Granite Crusher internet publicity site is that the key word "win-win culture" crushing granite Granite Crusher service provider - Hengtong Machinery advocates "win-win cooperation", which means to achieve win-win both internally and externally. Internally, it is Hengtong Machinery employees themselves. The company creates a good atmosphere, ambitious goals, creates a comfortable Hengtong Machinery cultural environment, employees achieve their own career goals and growth, and Hengtong Machinery achieves their interests goals, which is a virtuous circle of "win-win cooperation". Externally, Hengtong Machinery has created good crushing granite Granite Crusher products and services, and customers have been recognized, providing crushing granite customers with a good service experience, which is also "win-win", and the sense of trust has been further strengthened. This is Hengtong Machinery complementary ecological win-win.